The forensic engineering team (LPI) engaged to identify the root cause of the two fissures/fractures which caused the emergency closure of San Francisco’s new Salesforce Transit Center, a month after it opened, has reached a preliminary conclusion and a possible fix has been drafted.

According to the team, the probable cause of the fractures appears to be “the formation of cracks in the girder weld access [holes]” that were cut in the flanges prior to the beams being placed into service. More specifically, for the engineers in the room:

1. Initially, shallow (micro) surface cracks developed during thermal cutting of the weld access holes in the highly hardened and brittle martensitic surface layer [of the beams].

2. Thereafter, larger pop-in cracks formed in two of the four flanges, potentially during butt welding of the flange plates.

3. Black, tenacious, high temperature oxide was present on both the shallow surface cracks and the larger pop-in cracks, confirming that both crack types formed at elevated temperatures.

4. The fracture origins were located in the mid-thickness of the flange where low fracture toughness, as confirmed by CVN [(Charpy V-Notch)] toughness testing, provided little resistance to rapid, low-energy, brittle fracture.

5. CVN testing was performed on all flange samples at the top, ¼ depth, mid- thickness, ¾ depth, and bottom. ¼ depth CVN results were found to be consistent with the project specification and girder plate mill certifications.

6. Rapid, low-energy fracture of the flanges occurred as the girder was subjected to service loading on top of the normal residual stresses due to welded fabrication.

While further material testing and stress analyses are underway and will be considered in the final assessment due next month, it appears that the cracked flanges, which have maintained “sufficient capacity to support the building dead loads and occupancy loads,” can be fixed in place and the adjacent beams and columns were not overstressed by the fissures. Otherwise, the flanges can be easily replaced with sturdy weld neck flange welding to further support the weight if needed.

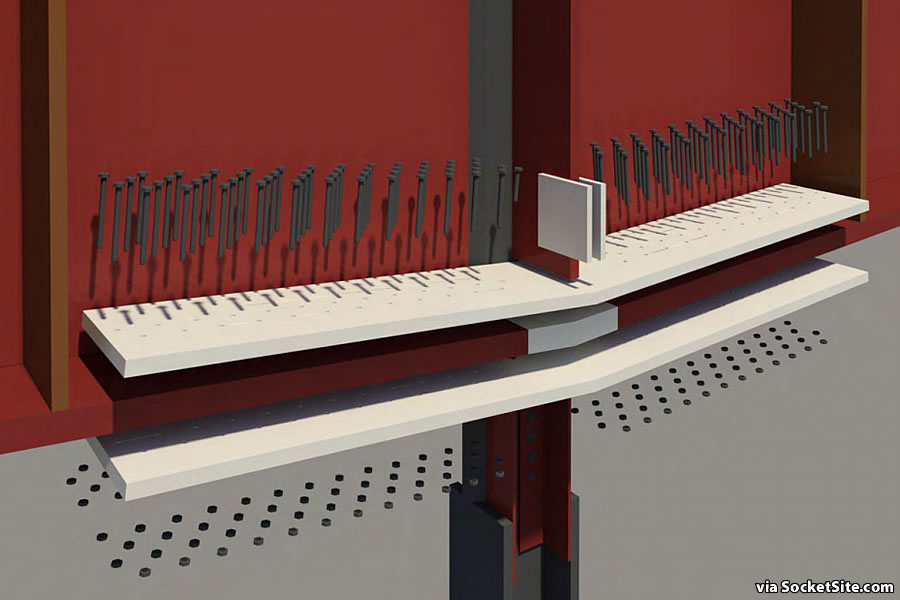

And as proposed by Thornton Tomasetti, the compromised areas of the flanges could be ground to a smooth surface, after which cover plates would be installed above and below and bolted together, restoring the beams to their original design capacity. However, whether we see someone or a team walking about in their welding helmet that meets the ANSI standards, we’re not sure what the plans are yet.

In terms of timing, a peer review of the findings and proposed fix are not expected to be reached until January, after which the fix will be implemented and a new structural evaluation will need to be performed. And as such, the Salesforce Transit Center will definitely remain closed through the end of this year and likely through the first, if not second, quarter of 2019, as we first reported earlier this week.

Thanks for the engineering details, I bet I won’t read those in the Chron or SFGate.

Let’s all raise a glass to the sublime utility of threaded fasteners.

To Science!

Even the possibility of “through the… second [ ] quarter of 2019” seems a bit extreme.

Perhaps, it will depend upon how the peer review reacts to the findings and plan. And of course, with the root cause having been identified, it raises the question of whether other girders in the center were exposed to the same types of cuts and welds but haven’t (yet) cracked.

Ugh, hadn’t thought of that possibility. Guess it depends upon whether similar welding access holes were cut in the beams not spanning Fremont and First Streets.

Perhaps wishful thinking, but “the fix” seems simple enough that it shouldn’t take too long so long as the peer review is in agreement.

In the other thread mvp implies that the weld access holes were not required:

“These were supposed to be weld access holes. The construction team had already welded without them but the project management team insisted they be cut anyway. So a square hole that was not required was then cut into the flange.”

If that’s the case then there’s a bigger story here of fumbled project management. It is not uncommon for someone higher in the management chain (sponsor, manager, architect) to request something wrong that builders begrudgingly comply with.

The good news is that if the source of the flaw is the creation of the weld access holes then the fix becomes a matter of identifying all of those holes and then fortifying them. In other words the scope of the repair is known and limited. It would be worse if the the problem were a bad batch of steel, then everything would need to be inspected or replaced.

Oh come on: are you going to have us believe a project that came in on-time and underbudget – well, some multiples of each…”close enough for government work”, as they say – got something wrong?

Back to the diagnosis, I’m confused: I thought the fissure was in the web of the beam – you know, the part that actually carries (almost) all the weight – the flange provides stability/stiffness, but only a small amount of load-carrying; did I miss something or is this only part of the remedy?

The flanges are responsible for virtually all of the bending moment and literally all of the buckling loads.

Thanks (I guess what I missed was Statics II…analysis of the members we treated as lines/vectors in Statics i). Well, anyway, the cracks were in the flange(s), so my thoughts had no bearing anyway….no pun intended.

Several sources for my statement. Key take away is:

“In March 2015, a firm enlisted to help oversee the project, Skanska, noted that Herrick Corp. had nearly completed the welding work without creating the required access holes. Herrick “is asking if the hole is required,’’ according to an entry in Skanska’s quality control log at the time. “Skanska QC (quality control) will further investigate this issue.” The following month, a log entry made it clear that the holes were ordered after the fact to eliminate an apparent problem where two welds came together”

“…a log entry made it clear that the holes were ordered after the fact to eliminate an apparent problem where two welds came together”

Does this mean the initial weld was observed to be substandard and then access holes were opened to rework the weld up to specs?

In the most generous reading of the source the best you can say is “maybe”. But general consensus seems to be the rat hole was on the task list and some pencil pusher simply wanted this task done. Why Herrick didn’t push back is the big mystery here.

I’m still suspicious of the proximity of these stress cracks to the sinking Millenium. In other words that there is subsidence in this area than results in everything sinking, in this case the sky ridge portion over the street.

Well, that’s a crank theory and the explanation given here makes real sense. Nobody should ever cut a square hole in metal, for any reason. It concentrates stress at the corners of the holes. I think I learned this in my very first semester as a mechanical engineering undergrad. Of course, maybe beam welders aren’t trained engineers.

For what it’ worth, the “corners” of the square-ish holes were (slightly) rounded.

As a Berkeley trained engineer – I’ve found most beam welders are more competent that a lot of engineers out there. 🙂

While most engineers can do a fair amount of math – they can’t give a accurate account of what is happening in the heat affected zone when actually welding steel this big.

It’s not enough to understand the desired results – you have to have a firm grasp of the actual fabrication process – the means and methods of the people attaching the pieces together.

It’s kind of like the difference between cooking croissants and running a bakery. They are related but not the same.

I’m totally with you there. An engineer can easily draw something that pencils out but can’t be built. In some fields we have “design for manufacturing” guidelines but that does not really translate from mass production to unique large-scale structures. Still, someone on this job should have been able to say the holes should be cut circular, or they should be cut with a water jet instead of a torch, or that the holes should be included by the manufacturer prior to heat treatment. Field changes have been responsible for many notorious engineering disasters and this could have been one.

Prime contractor got permission from the lead engineer to move just two bolts in the Hyatt Regency walkway collapse. It led to 114 fatalities…

Actually, if you had been keeping up, the transbay center wants to float up, not sink down.

The rumor is that they have evidence that the Transbay Center is SINKING. They are trying to cover it up. Maybe SS can do some digging?

I heard the opposite. All the tall heavy buildings surrounding the Transbay Center (plus over-weight pedestrians and heavy SUVs) are causing the Center to float!

According to the report: “…larger pop-in cracks formed in two of the four flanges, potentially during butt welding of the flange plates.” If cracks occurred during welding, why weren’t they immediately noticed?

Metal cracks start out short and hair thin. Welding splatters a lot of crud. Those newborn cracks might be easy to miss. Later they become more obvious.

Thornton Tomasetti is a great consultant. We have used them for just about everything we do.

Tough to be very impressed without knowing who you are and what you do.

So … in other words, critical welds were not inspected during construction. In an earthquake zone no less. WTF.

I just have a question….why was this, the billion dollar bus station built there in the first place. The Cal Train Depot would have been the best spot for San Francisco’s main train station. The current temporary bus terminal does that function perfectly well…..So what we have know is a monumental boondoggle that STILL isn’t connected to any rail lines.

What we have is a huge landmark building and elevated park, with a public space below it. The way this building was built was to yell about transit, global warming, whatever to get the PC crowd behind it as a public good. None of that is particularly important to this project, though. The building is built and it will be hugely profitable, and is a big improvement over what was there before. Not at all a boondoggle.

The Caltrain station at 4th and King is not downtown. Train stations work so much better when they are downtown. (Granted, the city has screwed up building it. But the original idea to put the train station downtown was the correct idea.)

The transbay terminal location has more jobs and residences nearby than all other Caltrain stations combined, including the current terminus at 4th and King.

UPDATE: Salesforce Transit Center Repairs Underway